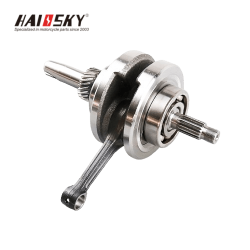

OEM Motorcycle Parts

Category: Motorcycle Crankshafts - Balanced & Trued Assemblies

About Motorcycle Crankshafts

The motorcycle crankshaft is one of the most critical components in the engine, responsible for converting the linear motion of the pistons into rotational motion, which ultimately powers the motorcycle’s wheels. Without a properly functioning crankshaft, the engine cannot operate efficiently, and the bike won’t move. The crankshaft’s durability, precision, and balance are essential for smooth engine performance, fuel efficiency, and overall ride quality.

Crankshafts are typically made from high-strength materials like forged steel, cast iron, or aluminum, depending on the engine’s design and performance requirements. They are engineered to withstand immense stress and heat, making them a robust yet wear-prone part of the engine.

Types of Motorcycle Crankshafts

Motorcycle crankshafts come in various designs, each tailored to specific engine configurations and performance needs. Here’s a breakdown of the most common types:

Single Crankshaft:

Found in single-cylinder engines, this is the simplest and most common type of crankshaft. It’s cost-effective, durable, and requires minimal maintenance, making it ideal for entry-level motorcycles and commuter bikes.

V-Twin Crankshaft:

Commonly used in Harley-Davidson and other cruiser motorcycles, V-Twin crankshafts are designed for engines with two cylinders arranged in a V-shape. They provide a distinctive rumble and deliver strong torque, making them perfect for riders who prioritize power and low-end performance.

Parallel Twin Crankshaft:

Used in parallel-twin engines, these crankshafts offer a balance between power and efficiency. They are popular in mid-range motorcycles and provide smooth power delivery, making them suitable for both city riding and highway cruising.

Triple Crankshaft:

Found in three-cylinder engines, triple crankshafts are known for their lively and responsive performance. They deliver a unique combination of smooth power delivery and high-revving capability, making them ideal for sporty and adventurous rides.

Four-Cylinder Crankshaft:

Designed for high-performance motorcycles with four-cylinder engines, these crankshafts are built to handle high RPMs and deliver smooth, consistent power. They are commonly used in sportbikes and superbikes, offering exceptional speed and acceleration.

Specifications and Maintenance of Motorcycle Crankshafts

Motorcycle crankshafts are engineered to meet specific performance and durability standards. Here are the key specifications to consider:

Material: Crankshafts are typically made from forged steel, cast iron, or aluminum. Forged steel offers superior strength and durability, while aluminum is lighter and ideal for racing applications.

Design: The crankshaft’s design includes offset journals, crank pins, and counterweights to ensure smooth operation and balance.

Size and Stroke: The crankshaft’s stroke length determines the engine’s torque and power output. Longer strokes provide higher torque, while shorter strokes allow for higher RPMs.

Bearing Journals: These are precision-machined surfaces that support the crankshaft and reduce friction. Proper lubrication is essential to prevent wear and damage.

Counterweights: These balance the crankshaft and reduce vibrations, ensuring smooth engine operation.

Maintenance Tips:

Regular Oil Changes: Clean, high-quality engine oil is crucial for lubricating the crankshaft and reducing friction. Follow the manufacturer’s recommended oil change intervals.

Monitor for Unusual Noises: Grinding, rattling, or knocking sounds may indicate crankshaft issues. Address these symptoms immediately to prevent further damage.

Follow the Manufacturer’s Maintenance Schedule: Regular inspections and maintenance can help identify and resolve potential problems before they escalate.

Check for Wear and Damage: During servicing, inspect the crankshaft for signs of wear, cracks, or misalignment. Replace it if necessary.

How to Choose the Right Motorcycle Crankshaft

Selecting the right crankshaft for your motorcycle is crucial for optimal performance and longevity. Here are the key factors to consider:

Compatibility: Ensure the crankshaft is compatible with your motorcycle’s make, model, and engine type. Using an incompatible crankshaft can lead to engine damage.

Quality: Opt for high-quality crankshafts from reputable brands. A well-made crankshaft ensures durability, smooth operation, and reduced vibrations.

Material: Choose a material that suits your engine’s requirements. Forged steel is ideal for durability, while aluminum is better for lightweight performance.

Budget: While cost is a factor, prioritize quality and compatibility over price. A high-quality crankshaft may cost more upfront but will save you money in the long run.

How to Replace a Motorcycle Crankshaft

Replacing a crankshaft is a complex task that requires mechanical expertise and the right tools. Here’s a step-by-step guide:

Gather Tools: You’ll need a socket set, torque wrench, crankshaft puller, crankshaft installer, and other tools for disassembling the engine.

Drain Engine Oil: Start by draining the engine oil and removing the crankcase to access the crankshaft.

Disassemble Components: Remove the flywheel, connecting rods, and other components to reach the crankshaft.

Remove the Old Crankshaft: Use a crankshaft puller to gently remove the old crankshaft. If it’s stuck, use a hammer and punch to loosen it carefully.

Install the New Crankshaft: Clean the crankcase and use a crankshaft installer to fit the new crankshaft. Ensure it’s properly aligned with the connecting rods and other components.

Reassemble the Engine: Reassemble the engine in the reverse order of disassembly. Tighten bolts and screws to the manufacturer’s torque specifications.

Refill Engine Oil: Fill the crankcase with fresh engine oil and check for leaks.

Test the Engine: Start the engine and listen for unusual noises. Let it run idle for a few minutes to ensure everything is functioning correctly.

Q&A

Q1: What is a crankshaft on a motorcycle?

A1: The crankshaft is a crucial engine component that converts the up-and-down motion of the pistons into rotational motion, which powers the motorcycle’s wheels.

Q2: What are the symptoms of a bad crankshaft in a motorcycle?

A2: Common symptoms include unusual noises (grinding, rattling, or knocking), excessive vibrations, loss of power, and difficulty starting the engine.

Q3: How do you know if a crankshaft is bad?

A3: Inspect the crankshaft for signs of wear, cracks, or misalignment. Unusual engine noises and performance issues are also indicators of a bad crankshaft.

Q4: What destroys a crankshaft?

A4: Lack of lubrication, poor maintenance, excessive heat, and improper installation can lead to crankshaft failure.

Q5: How much does it cost to replace a crankshaft?

A5: The cost varies depending on the motorcycle model and the type of crankshaft. Labor costs can also add up, so it’s advisable to get a quote from a professional mechanic.

Q6: What is the main purpose of the crankshaft?

A6: The crankshaft converts the linear motion of the pistons into rotational motion, which drives the motorcycle’s wheels and powers the bike.